On the air with The Planker!

After a few months of casually melting solder, The Planker made it's maiden voyage yesterday afternoon when I enjoyed a brief chat with Lauren, WD5HIO, in central Ohio. I'm very pleased to say that nothing exploded or otherwise malfunctioned, and Lauren commented that I had a very nice signal with "excellent audio". Yes!!!!

So, what is all this Planker nonsense? It stems from an email exchange I had with Pete, N6QW, earlier this summer. Pete had been working on a rig covering 40 and 60m, 60 being the only amateur HF band that I'd never operated on. At that time, I was putting the finshing touches on my "all-band" HF rig, and was getting a little frustrated because I'd built myself into a corner and was running out of space on the chassis.

Since I'd never been on 60, I became intrigued by Pete's rig, and thought that it'd be a good "rainy day" project for the summer if I kept it simple enough. At the same time, I wanted to avoid my bad habit of establishing a "form factor" for the chassis and trying to fit all of the circuitry within those confines, and, since I've had this 24" chunk of pine board kicking around for years, everything just clicked. As N2CQR says: TRGHS - The Radio Gods Have Spoken.

The architecture of the rig is very similar to Farhan's (VU2ESE) BITX: It's a single-conversion superhet SSB transceiver using bilateral IF stages.

Each individual stage is built as a module, the input and output impedance of which is 50 Ohms.

From left to right: The small board is a 7 pole LPF, behind which is the power amplifier (based on Farhan's RF386) and forward of which is the antenna relay and pre-mixer bilateral amplifier (based on W7ZOI's "TIA" circuit, using six 2N3904s.)

Moving to the back of the plank, the two upright transistors to the right of the PA handle the T/R switching. These are actually some bogus 2SC1969s that I bought on Ebay; they don't work at RF, but are adequate DC switches.

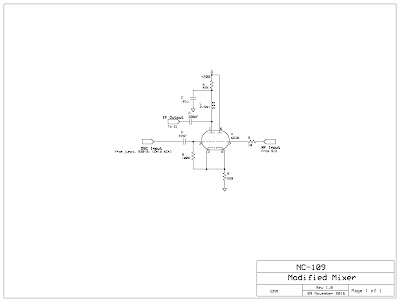

In front of the switch board is the mixer, a homebrew DBM using "matched" 1N4148 diodes. Forward of the mixer is the 20 MHz IF amplifier, another W7ZOI "TIA" module.

Underneath the crooked shield (right of the switch/mixer/IF amps) is the crystal filter, which I made from seven 20MHz CPU crystals. The bandwidth of the filter was set, largely experimentally, to 2.4 KHz, by selecting the appropriate shunt capacitors. I first modeled it on the computer and then adjusted it using a spectrum analyzer.

Moving to the right again, what you can't see (because it's behind the display panel) is the product detector/balanced modulator, which is the 2 diode single-balanced circuit stolen from the BITX.

The display panel is, well, a display panel... A small board behind the 7 segment display contains the 4511 driver IC, and the pushbutton steps through the five 60m channels and WWV at 5 MHz.

The next board is the synthesizer and MCU. I'm using an Arduino Pro-Mini to control a SI-5351, which provides the local and beat frequency signal sources. And no, phase noise isn't an issue.

Then, finally (if you've made it this far) is the transmit and receive audio board. The transmit audio amplifier is a pair of cascaded JFETS (J310), and the receive side uses a 2N3904 to drive an LM380-8.

If you're wondering about the handle: I added that to be funny - it technically makes it portable.

The transmitter outputs, eh, about 7-8 watts PEP using an IRF-510, though I just received a package from RF Parts and will be changing that to a proper RF device (Mitsubishi RD16HHF1) shortly.

The picture shown above is how the rig looked at the time of my QSO with WD5HIO. Later in the evening, I tidied-up the wiring a bit, but the circuitry remains the same.

One thing that I still need to do is implement a tone generator for CW: When I started this project, I wasn't aware that the FCC had revised the regulations allowing this mode, so it wasn't on my radar. That'll be handled in software, using the Arduino to generate the tone and cleaning it up with a RC LPF network.

Otherwise, there you have it. I'm debating whether to mount it on a chassis and put it in an enclosure, or leave it as it is... The crudeness of the breadboard is growing on me!

Update: Added a few lines of code, LC LPF and an input line for the CW Keyer. The Arduino did a marvelous job - told it the output a 1.5KHz square wave, and it did exactly that. So, with the proper attenuators, I'm feeding the tone into the mic circuit to put the CW signal right in the center of the channel, and a little back into the RX amp to provide a side-tone. Works great!

73 - Steve